|

Alpha™ Specifications

Designed to test QFN, DFN, QFP, and SO IC packages for most handler platforms, the Alpha™ Test Contacting Solution gives you visible results, lowering your cost of test, higher yields and up- binning of your product.

|

| Electrical Specification | |||||

| 1 | Electrical Length (mm) | — | — | ||

| 2 | Inductance | Self (nH) | 3.54 | 3.54 | |

| Mutual (nH) | — | — | |||

| 3 | Capacitance | Self (pH) | — | — | |

| Mutual (pH) | — | — | |||

| 4 | S21 (Insertion Loss/Bandwidth) | — | — | ||

| 5 | S11 (Return Loss/Bandwidth) | — | — | ||

| 6 | S41 (Crosstalk/Bandwidth) | — | — | ||

| 7 | Contact DC Resistance (mohm) | 10.0 | <= 30.0 | ||

| 8 | Current Carrying Capacity (A) | 4.00 | 4.00 | ||

| 9 | Current Leakage (pA) @ 10V | — | — | ||

| 10 | Decoupling Area (mm) | — | — | ||

| 11 | Peak Current (A @ 1ms) | 30.00 | 30.00 | ||

| Mechanical Specifications | ||||

| 1 | Physical Pin Length (mm) | — | — | |

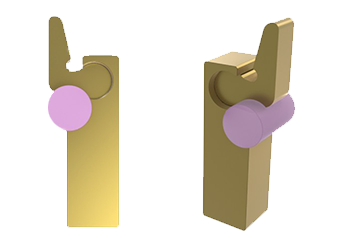

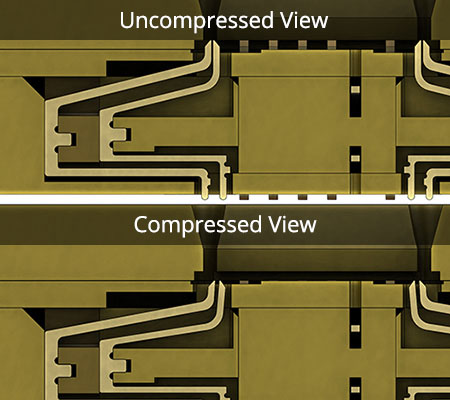

| 2 | Pin Uncompressed Height (mm) | 3.43 | 3.43 | |

| 3 | Pin Compliance (mm) | 0.200 | 0.200 | |

| 4 | Pin Tip Coplanarity (mm) | — | — | |

| 5 | Pin Wiping Length (mm) | <= 0.15 | <= 0.15 | |

| 6 | Gram Force Per Pin (g) | 20 to 30 | 20 to 30 | |

| 7 | Number Of Insertion | Housing | >= 6 Millions | >= 6 Millions |

| Pin (Matte Tin) | >= 500K | >= 500K | ||

| Pin (NiPd) | >= 500K | >= 500K | ||

| 8 | Operating Temperature © | -45 to 155 | -45 to 155 | |

| 9 | Socket Material | TORLON 5030 | TORLON 5030 | |

| 10 | Pin Material | BeCu-Ni-Au | BeCu-Ni-Au | |